Choosing the most effective feeding programme has never been more important given the unpredictability of the raw material market and lack of consistent supply of materials. The current raw material market appears to be more settled however, given recent events, the future is far from predictable. This also needs to be considered within the context of an ever-changing growing environment where the turkey’s response to a given feeding regime is influenced by enteric challenges, increased removal of antibiotics and in some cases removal of coccidiostats.

In such situations, it is critical that nutritionists can make informed decisions in order to choose the most efficient feeding programme for different circumstances.

Identifying the most efficient feeding programme starts with an understanding of the birds response to nutrient density. Energy and protein are the two main contributors to diet cost and therefore are the principle nutrients to consider from an economic point of view.

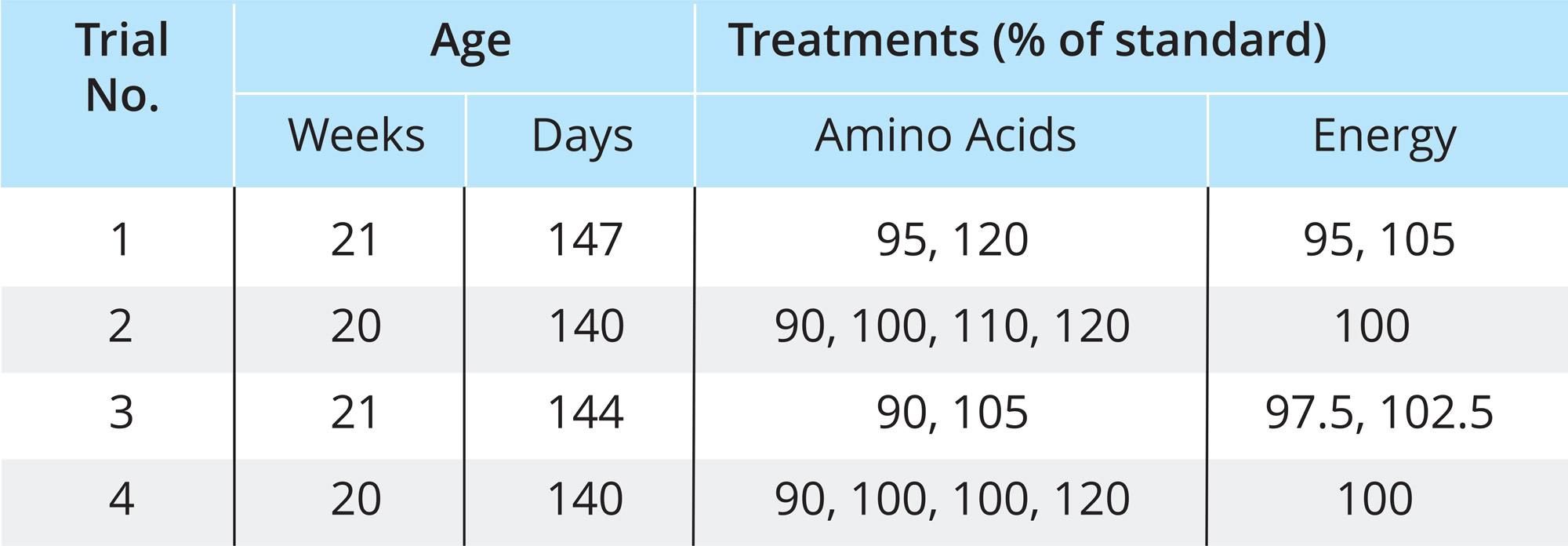

Aviagen® Turkeys Ltd, in collaboration with Moorgut Kartzfehn GmbH, conducted a series of trials examining the impact of various energy and amino acid densities on B.U.T. 6 male turkey performance. Each of these trials assessed different nutrient levels, Table 1 shows the amino acid and energy levels assessed, nutrient levels are expressed as a percentage of a commercial standard.

A summary of the ‘commercial standard’ feeding programme and nutrient levels are shown in table 2.

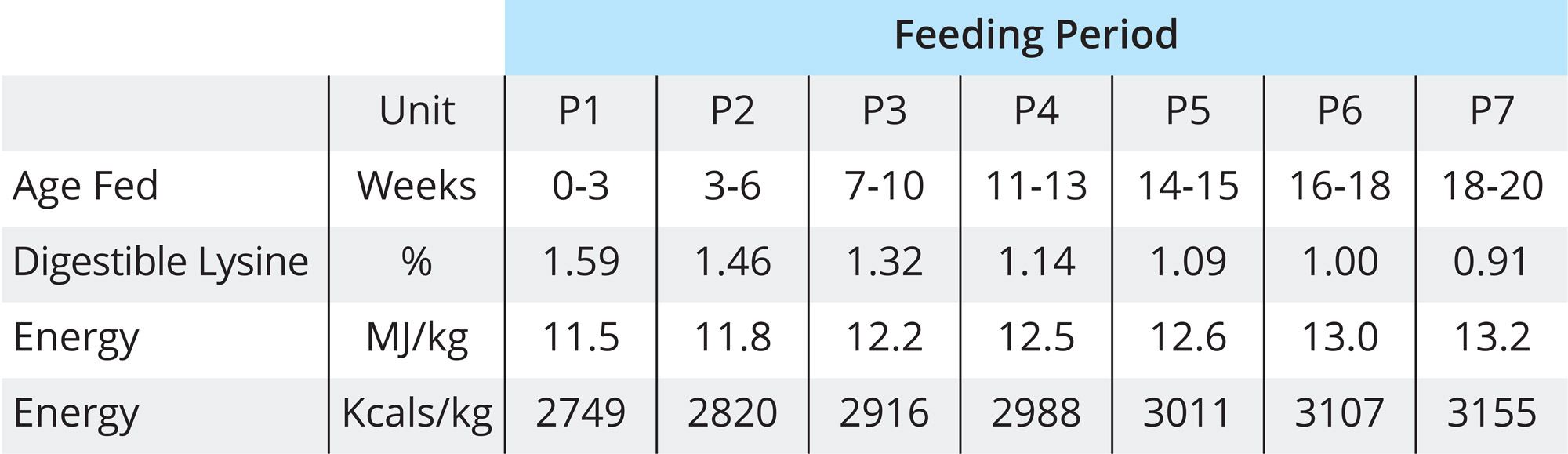

Performance data from these trials were collated to assess the response of turkeys to a range of nutrient densities. The surface plot graph (Fig.1a, b) shows liveweight and feed conversion ratio (FCR) responses to altering nutrient density.

Both liveweight and FCR are responsive to both amino acid and energy density (expressed as percentage relative to the 100% control), the response for both traits was optimised at the highest energy and amino acid density. The surface plot graphs also shows that energy density appears to impact positively on the response to increasing amino acid concentration suggesting that diet energy density should be considered when feeding higher amino acid densities.

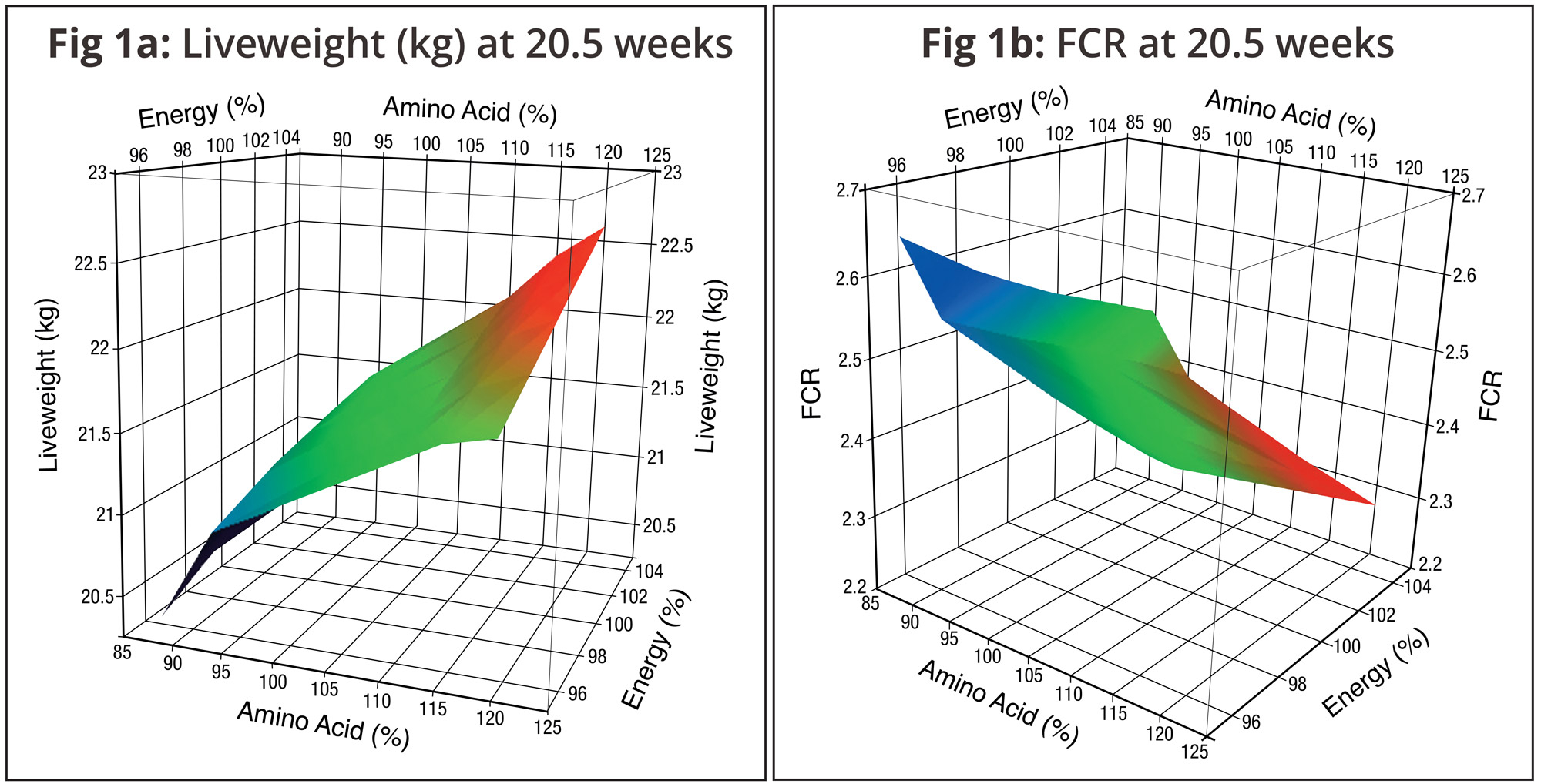

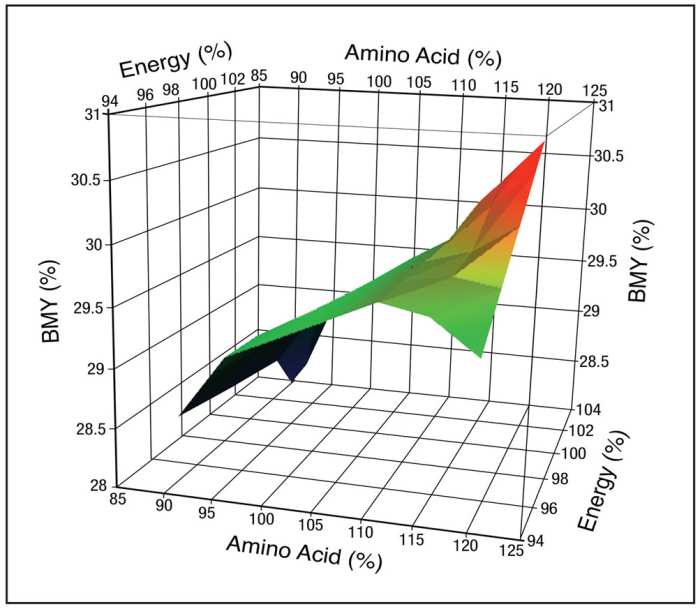

Processing traits were also assessed, as with liveweight and FCR responses, increasing nutrient density had a positive impact on breast meat yield (fig. 3). At lower energy densities, breast meat yield (BMY) showed a curvilinear response to increasing amino acid density. However, BMY continued to respond to increasing amino acid concentration at intermediate and higher energy densities, again, this reinforces the importance of considering both nutrients particularly when optimising processing yield.

In summary, the data demonstrates the ability of the modern bird to respond to a wide range of nutrient levels. Liveweight, FCR and portion traits are responsive to nutrient density and show optimal responses on or above the commercial standard.

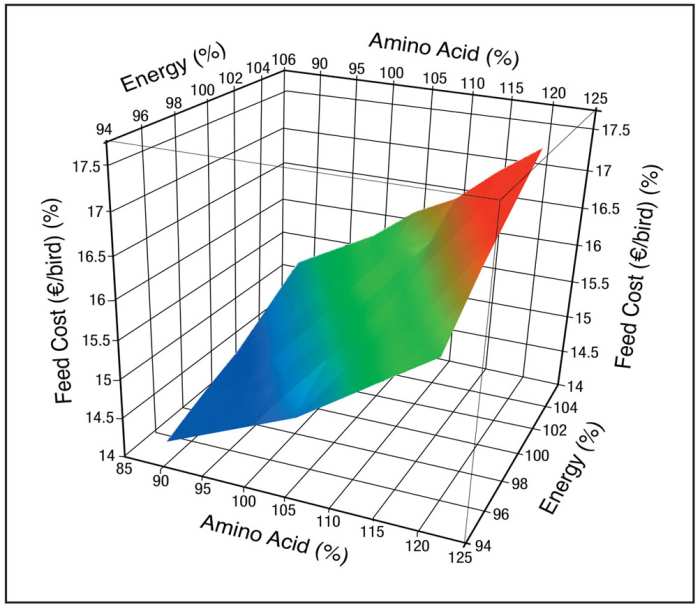

Having established performance responses to different nutrient densities, economic responses can also be derived. Feed cost per bird was calculated for each nutrient density fed, as expected feed cost increased consistently with increased nutrient density (fig. 3).

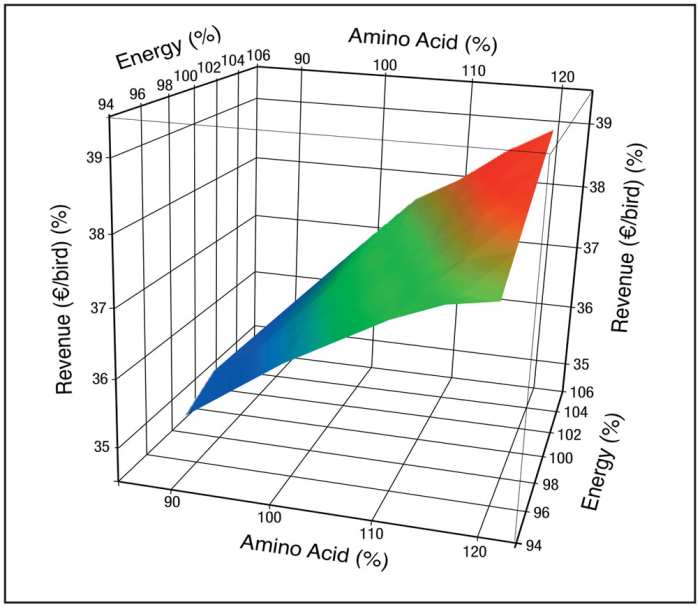

Revenue per bird was also estimated across all nutrient densities (fig. 4), revenue increased with increasing nutrient density.

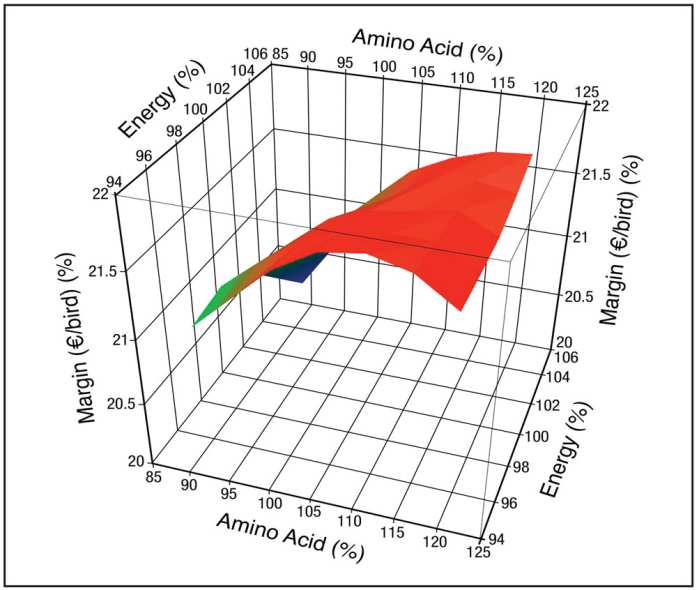

Margin (after feed cost) was calculated by estimating the difference between revenue and feed cost per bird at each nutrient density. By examining the profile of the surface plot graph the effect of nutrient density on farm margin can be established (fig. 5).

Based on existing raw material costs, higher margin (after feed cost) is achieved at higher amino acid density and a lower energy density than the existing standard. Optimal farm margin is achieved at an amino acid density above the standard (105% of standard) and at the lowest energy density (95% of standard). The lowest farm margin was at the highest energy (105%) and lowest amino acid concentration (90%). Higher energy densities may achieve higher biological performance however this is outweighed by an increased feed cost (€/bird) relative to lower energy density levels.

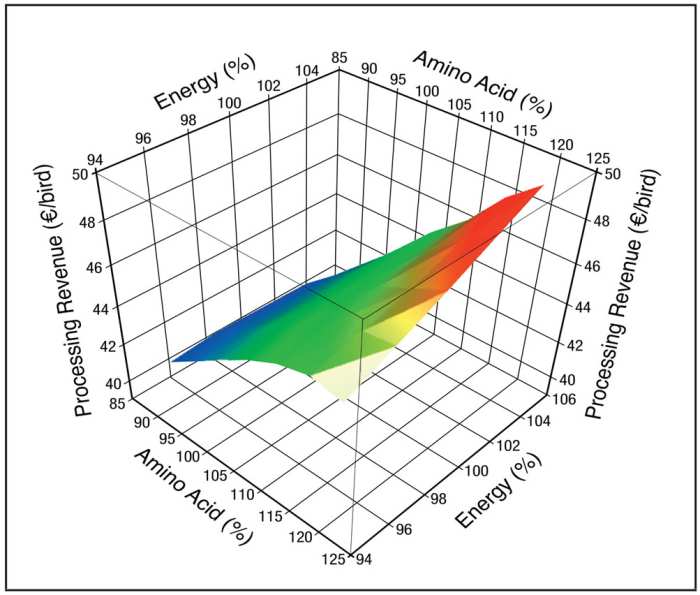

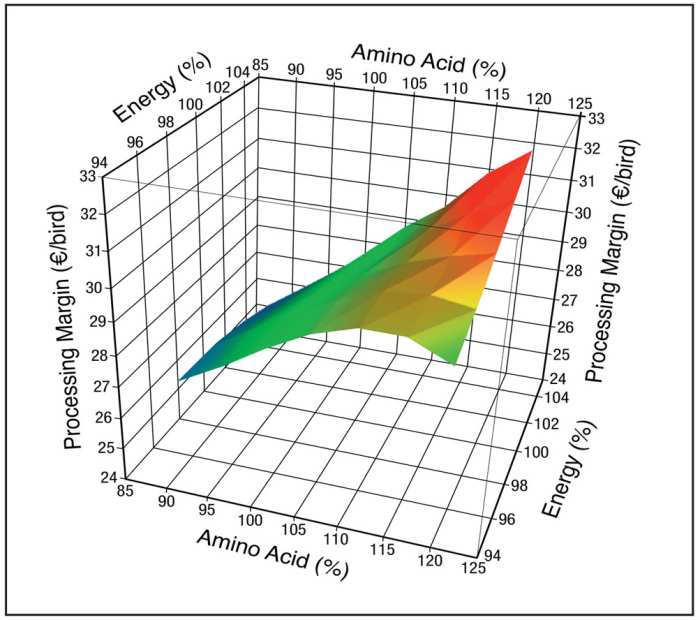

The same approach can be taken to derive an estimate of margin for processed products, margin was estimated at each nutrient density based on revenue (the value of breast meat yield) minus feed cost per bird. Processing revenue is highly responsive to nutrient density, as nutrient density increases so too does revenue (fig. 6). Contrary to farm margin optimal processing margin was achieved at both the highest amino acid and energy density (fig. 7). This reflects the response of breast meat yield to both nutrients and the higher revenue associated with processed products relative to liveweight. Increasing amino acid density without a concomitant increase in energy results in lower margin, lowest margin was at the lower amino acid densities.

In summary, the data demonstrates the ability of the modern bird to respond to a wide range of nutrient levels. Liveweight, FCR and breast meat yield are responsive to nutrient density and show optimal responses on or above the commercial standard. Optimal economic perfor-mance is realised at different nutrient densities and are dependent on the objectives of the business, for example farm or processing margin. Feed prices have a significant impact on the optimal diet nutrient density and highlights the importance of nutritionists reviewing feeding programmes especially during periods of volatile raw material prices.