The turkey industry is going through the most turbulent period of raw material price increases resulting in feed prices being at their highest in the industries history. Cereal prices are reducing as harvest progresses, however wheat stocks are still likely to remain tight as the situation with Ukrainian grain exports still looks uncertain so there is a likelihood that wheat prices will remain firm. Despite US soybean yields and output set for record highs the soya market also appears firm.

In a situation where feed prices are escalating there is a strong case for evaluating the current feeding programme. It is important to remember that any significant reduction in the nutrient specification of the diet has the potential to negatively impact on flock performance and consequently output. Any change in the nutrient specification of the diet therefore needs to be carefully assessed and based on the best available evidence. Aviagen Turkeys Ltd have published information demonstrating the impact of altering the nutrient density of the diet on bird performance, information such as this needs to be referred to when considering such changes, this data can be used by the nutritionist to make informed decisions about the impact of any changes to diet nutrient specification levels.

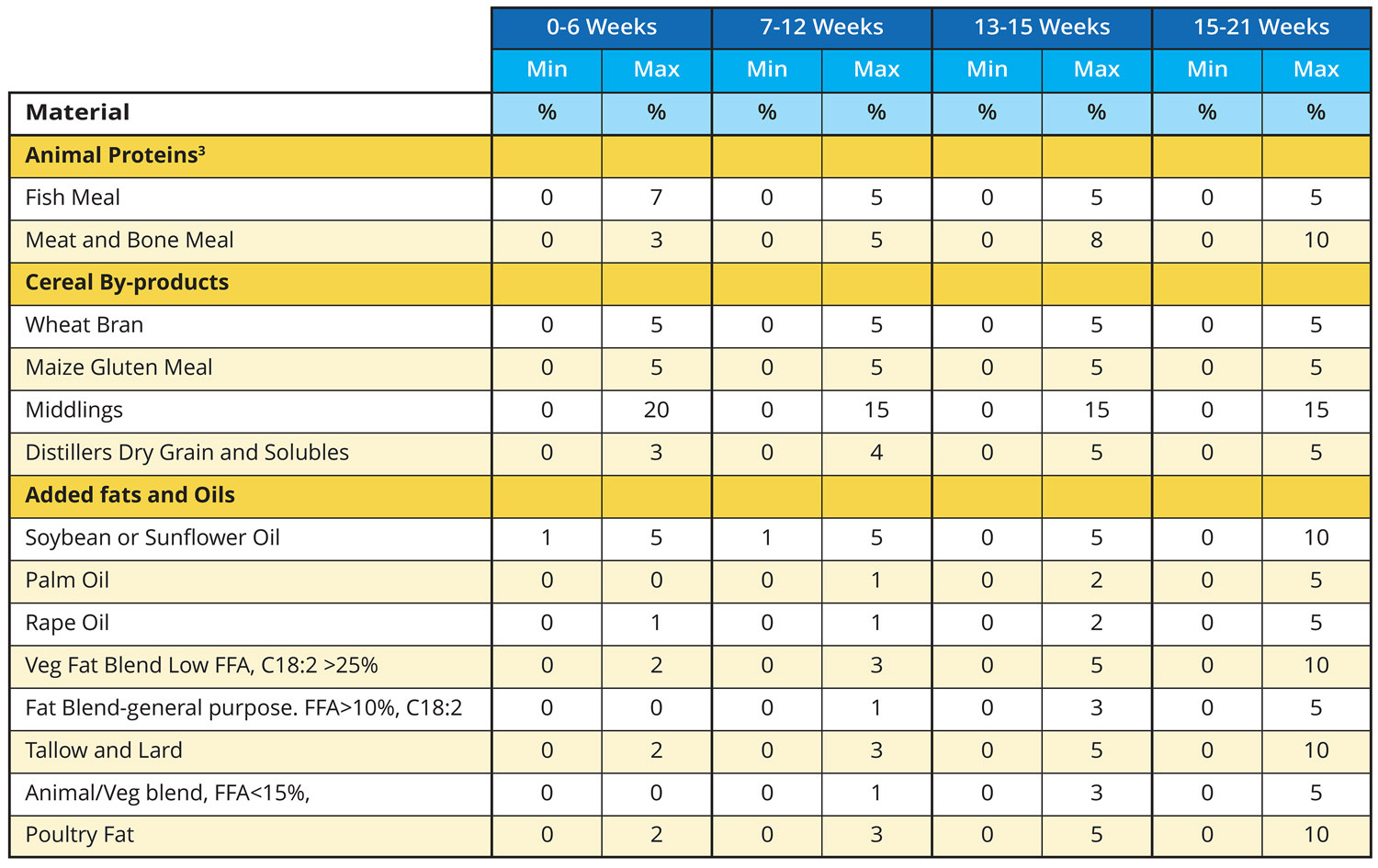

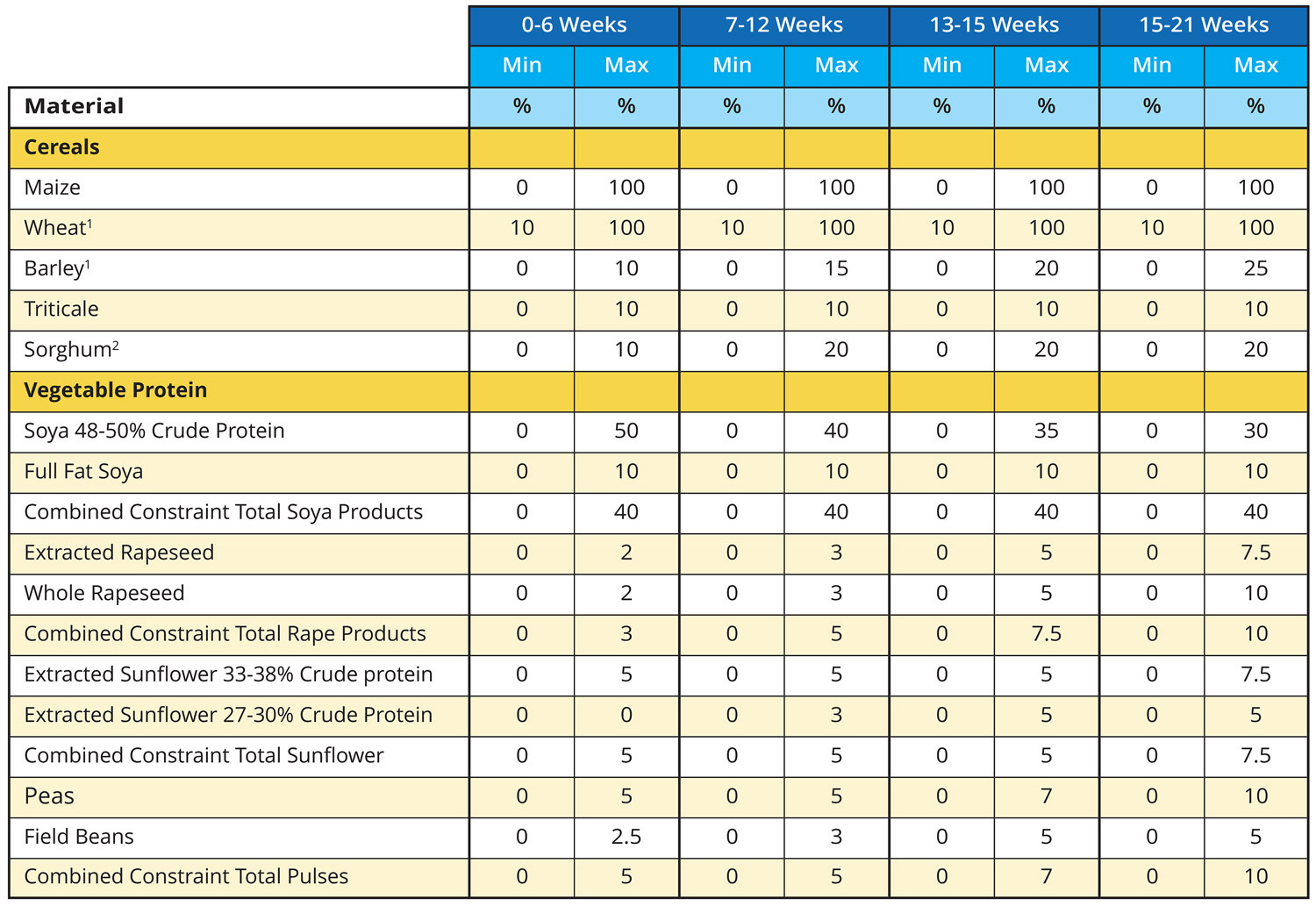

Constraints are placed on raw materials when least cost formulating as this can have a significant impact on formulation costs. Constraints are placed on ingredients for different reasons, for example there may be a maximum constraint on soya-based materials as these contain anti-nutritional components which may be detrimental for bird health and performance. The inclusion rate of other materials may be restricted due to physical or milling constraints, for example excessive levels of maize may have a detrimental impact on pellet durability. The exact level such constraints are set at are almost always based on a subjective assessment along with an element of insurance or safety factor. Constraints may also be based on convention or whatever constraints have historically been in use. In a rising raw material cost base it is prudent to challenge existing constraints and capture any cost saving opportunities whilst maintaining the nutritional integrity of the diet.

Wheat is valued not just as an energy source but also aids in pellet quality in its ‘pellet binding’ properties, however when wheat prices escalate other cereals may be more cost effective, for example maize or sorghum. Neither of these cereals have the same ‘pellet binding’ effect of wheat however use of pellet binding agents, including a minimum quantity of wheat-based products, while also adapting feed processing techniques can overcome these issues.

The inclusion of alternative proteins to soya is also important to consider not just from an economic standpoint but also from a carbon emissions viewpoint. Although sunflower meal is currently in short supply peas, beans and rapeseed meal are suitable alternatives.

It is worth investigating what other materials are available in the feed mill which may currently be used in other species but not currently offered to turkey diets. Also, the feed mill purchaser may be aware of other materials available on the market which have previously not been considered for turkey diets.

Distillers dried grain and solubles (DDGS) is another protein source which can be cost effective, inclusion rates are limited to no more than 4% to 5% in diets due to the risk of mycotoxin contamination. Maize gluten meal is one of the highest protein density cereal by products, consideration should be given to the low lysine content so the diet should be balanced accordingly. Maize gluten can be included up 5% to 7% in turkey feeds.

Processed animal proteins (PAPS) are used successfully in diets and now permitted for use in the EU under strict control measures, only feed for species for which the use of poultry PAPs is permitted can be produced on the same site and vice versa for pig PAPs. The number of feed mills that are 100% dedicated to pig feed or poultry feed is extremely low so, based on the current restrictions in use, it is unlikely PAPS will feature in turkey diets to a significant extent in the EU in the future.

A list of ingredients with suggested constraints are shown in the tables opposite.

Other less conventional protein sources such as insect meal and algae derived protein are considered viable alternatives to conventional protein sources however price and availability dictate these materials are used in more niche sectors such as specific aqua feeds and pet foods.

Lastly, additives such as enzymes increase the nutritional value of feed, this is particularly important in the current climate. It is important to liaise with suppliers to ensure their products are utilised to the maximum degree. Any new permitted technologies should be evaluated if demonstrated to be cost effective and safe to use.

Genetic selection results in strains becoming ever more feed efficient over time. The improvement in feed efficiency (FCR) of a 20kg B.U.T. 6 male birds has improved by 4 to 5 points in the past 3 years. The impact of this improvement in terms of feed usage per bird is significant, a 20kg bird will consume 0.8kg less over its lifetime. Based on current feed prices this reduction in feed intake equates to £0.28 per B.U.T. 6 male bird, all through genetic gain! It pays to consider what genetics are used in order to maximise the efficiency of today’s highly priced feed.

In summary:

1) Be cautious in reducing diet nutrient density with a view to saving feed cost, there may be consequences on flock performance.

2) Interrogate raw material constraints, capture cost saving opportunities while maintaining the nutritional integrity of the diet.

3) Consider alternative cereal sources and maintain feed physical quality.

4) Investigate alternative protein sources and if other materials are available in the mill or on the market.

5) Assess novel ingredients as some are becoming both nutritionally and commercially viable.

6) Optimise the use of feed additives to increase the nutrient contribution from feed materials.

7) Use the most efficient genetics to maximise the conversion of feed to live weight.

Ingredient Constraints

1 Assumes use of NSP enzymes 2 Low tannin varieties

1 Assumes use of NSP enzymes 2 Low tannin varieties