How Aviagen Turkeys’ Trials Farm works

Aviagen® Turkeys Ltd (ATL), trials facility has now provided breed performance results for nine years. The invaluable data collected here has helped to shape the final commercial cross used globally by our customers. This facility gives ATL the opportunity to examine and compare multiple breeds and their responses to nutritional and management techniques, helping develop advice on best practice for turkey producers and key breed performance objectives.

The site is situated in East Cheshire, UK, around 27 miles from Head Office. Strict biosecurity measures have been implemented on site, which include a shower in shower out policy, strict segregation from ATL production operations and a bird health programme consisting of comprehensive vaccination and environment swabs schedule, to name a few.

Image 1. Outside of farm

Image 1. Outside of farm

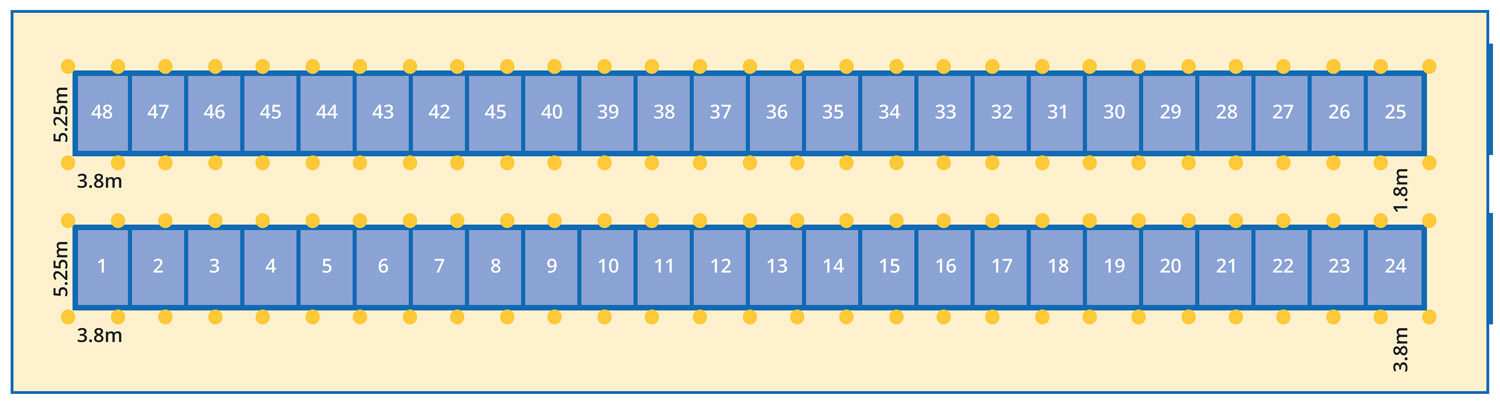

The trials facility consists of one 100m x 20m controlled environment house, containing 48 x 20m² replicated pens, each with a brooder, 2 bell drinkers and 2 feeders (see image 2). Each pen is managed as an individual flock where daily records of feed consumption, water consumption, litter use, house temperature and mortality with cause are taken.

Image 2. Layout of the trials facility

Image 2. Layout of the trials facility

The trials farm is managed by Ollie Davenhill, Farm Manager and Kate Harvey, Farm Worker who oversee the daily farm management and data collection. Hannah Swarbrick, Technical Development Manager & Luke Ramsay, Management Specialist are the designated contacts to coordinate the trials and support the running’s of the farm (See Image 3).

Image 3. Trials farm management team: Kate Harvey, Ollie Davenhill, Hannah Swarbrick and Luke Ramsay

Image 3. Trials farm management team: Kate Harvey, Ollie Davenhill, Hannah Swarbrick and Luke Ramsay

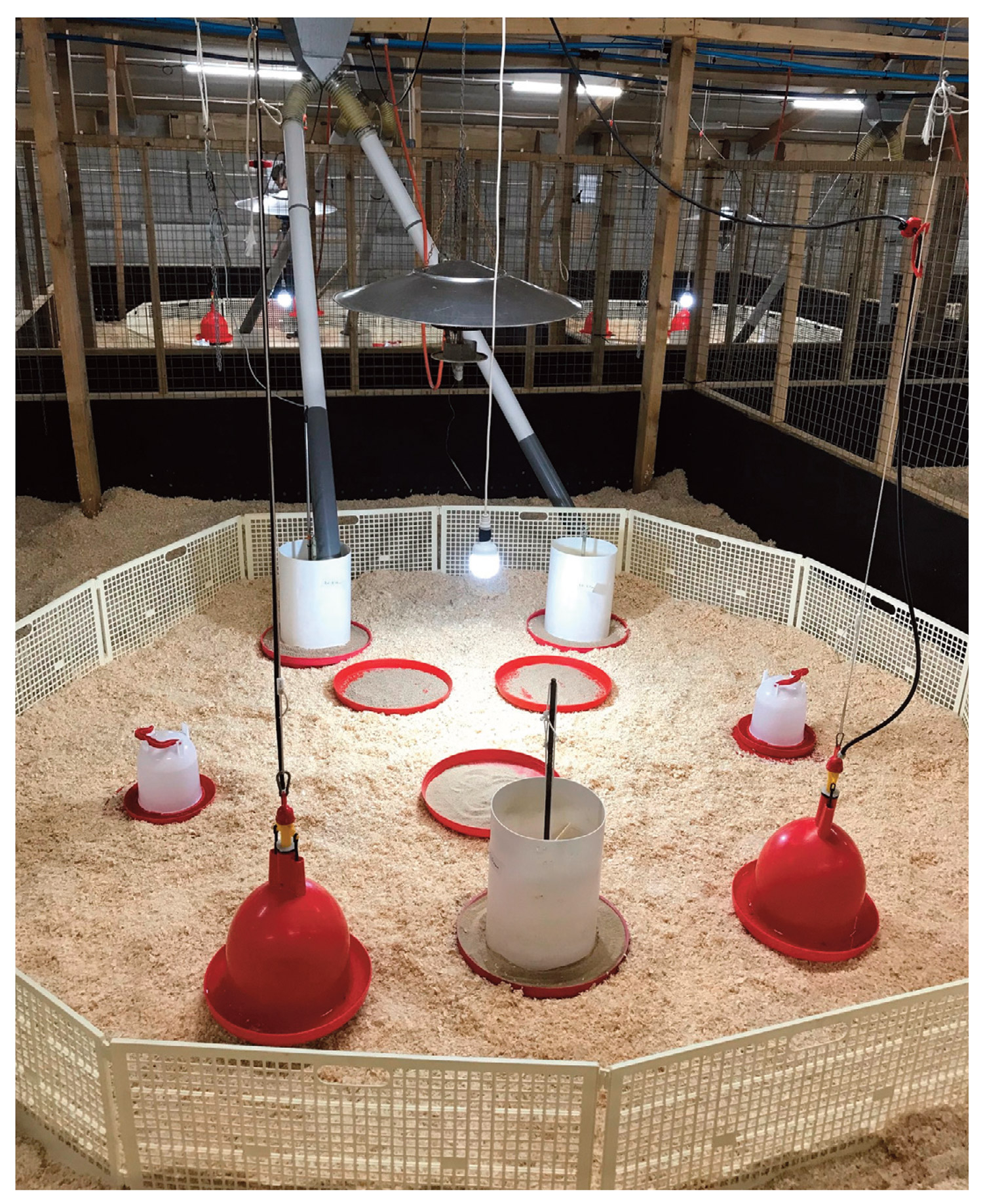

Poults arrive at the facility at day old, where two pens are placed together in brooding rings until 3 weeks of age and then spilt into final stocking densities (See Image 4). The birds are placed and housed as close to a commercial environment as possible, utilising realistic stocking densities to give representative results. We place both males and females in the trials and undertake routine measurements to keep track of their performance.

Image 4. Ring set-up

Image 4. Ring set-up

These measurements include individual and bulk weighing’s at day old, then again at 3, 6, 15, 18 and 20 weeks of age. Leg health scoring is undertaken at 14 and 16 weeks of age and footpad condition is scored after processing. We select 7 birds from each pen to go for processing at 15, 18 and 20 weeks of age, where components of each bird are weighed to calculate meat yield.

The facility has 8 feed silos with feed lines, which pass through into a central location within the shed. Feed is then weighed and transported by auger to each pen. Once the feed has made it to the pen, it is placed into an overhead hopper which connects to the two feeders (See Image 4). This automation allows accurate recording of feed consumed per pen over the trial lifetime, and delivery of specific diets to individual pens for nutritional trials. This is to assess how the birds react, gaining knowledge on the best way to feed the modern turkey.

Another advantage of recording feed consumption is that we can work out the feed conversion ratio (FCR) for each pen. We work out FCR in two ways, the first being what we call “economic” FCR which is the total amount of feed ingested divided by the weight of the birds which are alive. The second is called “technical” FCR which is the total amount of ingested feed divided by the weight of alive and dead birds.

As you’d expect the water is automated and consumption is measured on 4 separate lines which allows us to monitor and record the data of separate breeds or treatments.

The ventilation on the farm is through side wall inlet and roof extraction. The inlets are distributed evenly throughout the shed to give each pen as near as identical environment as possible. This type of ventilation system keeps the birds in their thermal comfort zone whether its summer or winter.

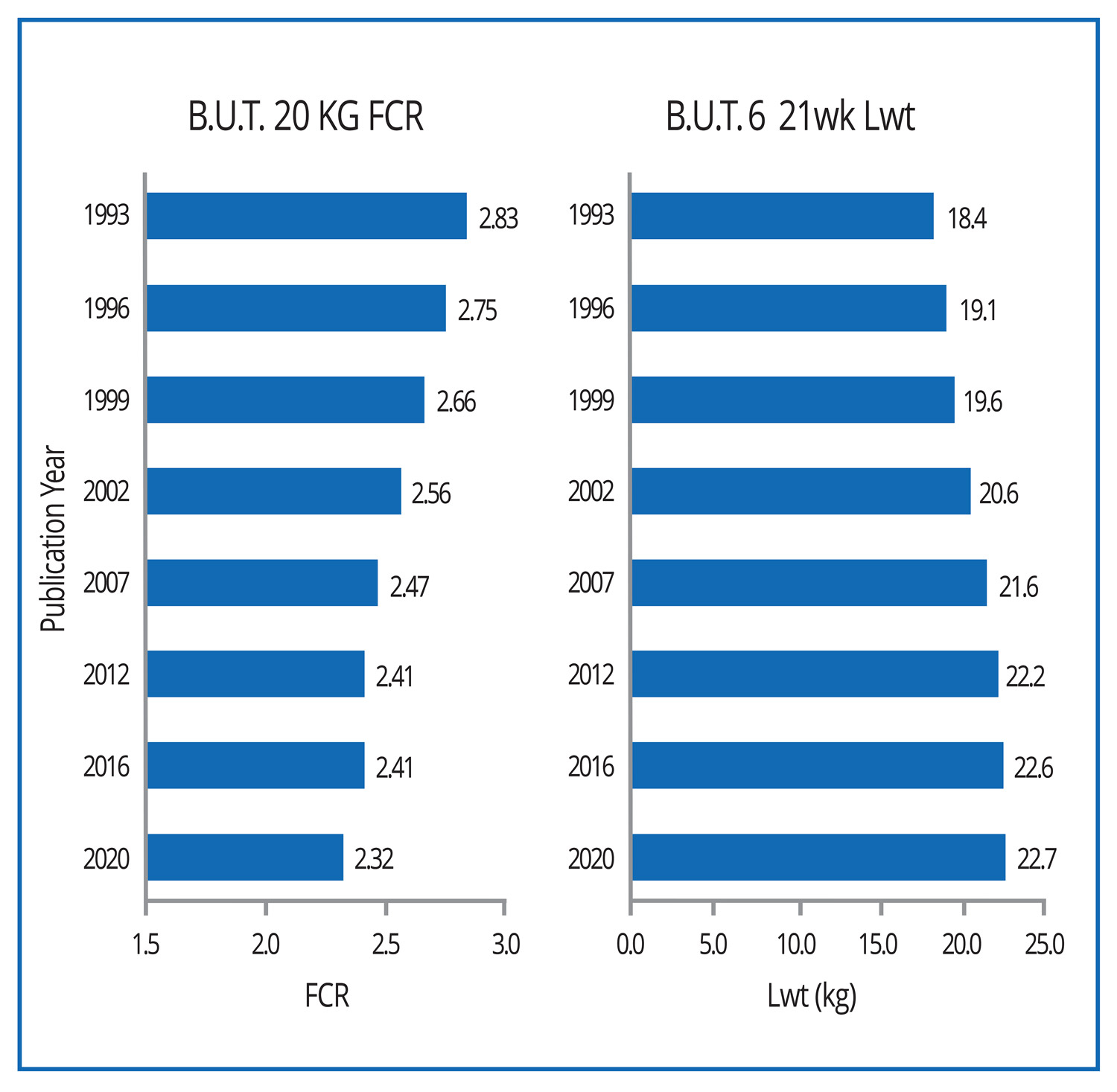

Ultimately, the data collected from our trials facility and collaboration trials has contributed to breed benchmarking and continually advancing results for ATL’s breeds (See Image 5). These resources combined provide our customers with the very best management advice, breed information and allows the team to make informed decisions within our breeding programme.

Image 5. FCR and Liveweight trends over time

Image 5. FCR and Liveweight trends over time