Water is an essential nutrient for birds. Providing a clean water supply throughout production promotes bird health, welfare and performance, which is important irrespective of the production system used. Water disinfection during production is an integral part of a good flock management system. Controlling bacterial contamination and biofilm formation in the drinking system is key to reducing bird exposure to harmful organisms and lessening the risk to spread disease.

Poultry houses are ideal environments for growing microorganism: It is a warm environment; has relatively low flow rates of water through the lines at certain times of the production cycle particularly during early rear and at night facilitating sedimentation and colonisation; and provides substrates microbes can thrive on like probiotics, citric acid, vitamins, organic acids, and vaccines. A symbiotic relationship between bacteria, yeasts and moulds leads to the formation of a biofilm. The complexity of water supply systems makes effective cleaning and disinfection (C&D) challenging; and delivery systems can be old and poorly/incorrectly maintained. Furthermore the turkey growing cycle is long with lots of opportunities for waterlines to become contaminated.

Cleaning the water lines between flocks is only half the battle. Even with a thorough cleaning, if a significant number of bacteria, fungi or yeasts are still present, then the biofilm has the potential to return completely in 2-3 days. Therefore, the last step is to establish a daily water sanitation program. This will benefit both the birds and the water system. The three most common sanitation systems are chlorine dioxide, chlorine with acidification and hydrogen peroxide.

As well as a continuous sanitizing of the water lines all bell-type drinkers must be washed with a disinfection solution at least three times per week. Wash thoroughly the bell and bowl with a brush or scrub pad. Wastewater should be poured into a bucket and removed from the house. Nipple drinkers should have a daily flush, which will keep water fresh and bacterial levels at a low level throughout the flock.

An important piece of information to know how effective the sanitisation program has been is the ORP value of the water; this can be done with a specific ORP reader, which are widely available. ORP stands for oxidation-reduction potential and it is a great way to find out if the water sanitation program is working. A strong oxidiser literally destroys viruses, bacteria and other organic material present leaving water microbiologically safe. An ORP value in the range of 650 and 700 millivolts indicates good quality water. A lower ORP value such as 250 millivolts indicates a heavy organic load that will most likely overwhelm a sanitizer’s ability to properly disinfect the water. The bottom line is utilise information on pH, ORP and chlorine level to determine if the sanitation program is effective and to also prevent equipment damage by the overuse of chemicals.

A couple of important points to note is that no sanitizers or any chemicals should be present in the water system when administering vaccines, medications or vitamins and do not mix different products in the same stock solution.

Choose a sanitizing cleaner that can effectively dissolve any biofilm or slime in the system. Some of the best products for this job are concentrated hydrogen peroxide solutions. Prior to using any strong cleaners, make sure standpipes are working properly so air pressure build up in the lines will be released. Consult equipment suppliers before using products to prevent unnecessary damage.

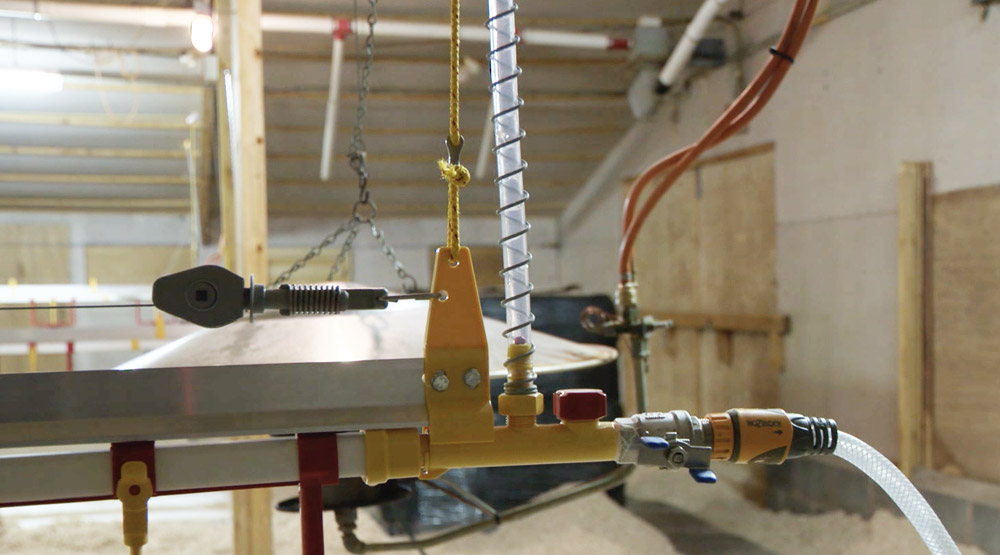

For the best results, use the products at the strongest concentration recommended on the label. Most medicators/ dosatrons will only allow concentrations between 0.8 and 1.6% of the original material. If you need to use higher concentrations, it is better to mix the stock solution in the large tank and then distribute it without using a medicator or Dosatron. For example, if a 3% solution is required, mix three volumes of the cleaner with 97 volumes of water for the final solution.

An excellent sanitizing solution can be made up by using a 35% hydrogen peroxide solution. Mix this as described for a 3% solution.

It takes 30–38 litres of water to fill and clean 30.4m of 1.9cm water line. If the building is 152.4m long and has two water lines, you should make up a minimum of 380 litres of sanitizing solution. Water lines should be designed so that they can be opened to drain completely when the cleaning is done.

Please note:

Always check dilution rates and follow manufacturers guidelines.

Steps 1-3 – Down time between flocks.

Step 4 – During the flock life cycle.